Shipbuilding

Smart designs: successful vessels

De Haas Shipyards has an excellent reputation in the field of specialised vessel construction. We have produced a number of successful concepts and delivered vessels that have proven themselves in operation.

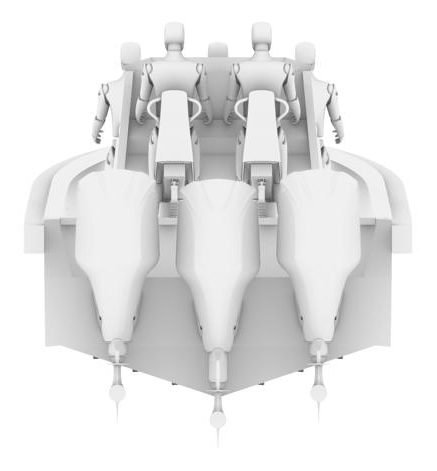

Smart designs

We combine the optimal hull shape with efficient, sustainable propulsion and apply technology and equipment relevant to the vessel’s scope of work. In some cases, our deliveries prove to be pioneers, driving demand in the market for similar vessels. Our Interceptor DHM1050 and the Seagull (for unmanned mine and submarine conflict) are just two examples of vessels that we have been requested to build more than once – always customised for specific client needs.

De Haas Nautical Lease

A number of our clients have taken advantage of our lease contract arrangements. With this, we provide design, build, finance and maintenance of a vessel. As a result, prices are fixed, ensuring predictable finances throughout the lifecycle.

The initial exploration

Once we have built a clear picture – together with you – of all your requirements, we will create a concept and basic design of the vessel. During this phase, we also consult with classification societies and inspection authorities to optimise efficiency in the process.

Next, our designers and engineers will translate the concept into a clear design, complete with 3D models, by which the design can be fine-tuned. This adds considerable value, resulting in cost savings, emissions reduction and optimal user-friendliness.

Production of hull and components

With the concept and basic design fully prepared, we can make the final calculations. In some cases, notably for high-speed vessels, we will create a scale model of the vessel’s hull for testing to ensure reliability, durability and performance.

Only when we are certain that the design meets all safety and function requirements will we proceed to a detailed design and the development of an efficient construction plan. At the end of this phase, with the design complete, construction of the vessel can begin.

Construction and completion

Throughout the design and construction (fitting out) phases, the vessel’s quality is continuously checked according to an integrated inspection and testing plan. This ensures that the vessel meets all requirements upon delivery, and also takes care of the process and documentation.

Commissioning, Testing, and Delivery

Upon completion of the vessel, there follows an extensive commissioning and testing period based on the previously established HAT and SAT protocols. After successfully passing all tests, the vessel is ready for delivery and use.